The DTF Wash Test is a crucial quality control measure for direct-to-fabric printing, simulating real-world washing conditions to assess colorfastness and print quality. This test is vital for custom apparel businesses as it provides insights into printing method performance, meeting industry standards and customer expectations, thereby enhancing business reputation. Implementing DTF Wash Tests offers significant advantages, especially when printing on dark fabrics, ensuring superior color accuracy and longevity. It streamlines production workflows, reduces turnaround times, and promotes sustainability in the industry. Successful tests require high-quality printer components, precise parameters, clean surfaces, pre-tested materials, even application pressure, accurate washing cycles, and meticulous post-wash inspection for optimal results.

Uncover the power of the DTF Wash Test, a game-changing method revolutionizing quality control. This test, an acronym for ‘Design to Factory Wash,’ simulates real-world conditions by subjecting products to rigorous washing processes. By understanding what a DTF Wash Test entails and its numerous advantages, manufacturers can ensure superior product performance. From enhancing durability to identifying design flaws, this strategy is a critical best practice for any production line, ensuring high-quality, long-lasting goods.

- What is a DTF Wash Test?

- Advantages of Implementing DTF Wash Tests

- Best Practices for Conducting Effective DTF Wash Tests

What is a DTF Wash Test?

The DTF Wash Test is a crucial quality control measure used to evaluate the durability and longevity of direct-to-fabric (DTF) printing. This test simulates real-world conditions by subjecting printed fabrics to repeated washing cycles, allowing for an assessment of colorfastness and overall print quality. By replicating the washing process, manufacturers can ensure that the vibrant colors and intricate designs produced through DTF printing techniques remain intact even after multiple launderings.

This testing method is particularly relevant for businesses specializing in custom apparel, as it provides valuable insights into the performance of their printing methods. The DTF Wash Test compares the initial color intensity with subsequent washings to determine any fading or degradation. Moreover, it offers a practical way to ensure that dtf printing for t-shirts and other textiles meets industry standards and customer expectations, ultimately enhancing the reputation of businesses offering such services.

Advantages of Implementing DTF Wash Tests

Implementing DTF (Direct to Film) Wash Tests offers a multitude of advantages for businesses and individuals in the printing industry, particularly when focusing on dark fabrics. This innovative technique revolutionizes the way we approach custom printing, ensuring superior quality and longevity. With a DTF Wash Test, printers can achieve vibrant, accurate colors even on darker garments, thanks to its ability to bond directly with the fabric’s surface. This process eliminates issues commonly found in traditional printing methods, such as fading or smudging after multiple washes.

Moreover, DTF printing for t-shirts and other textiles provides an efficient workflow. Direct to film printers streamline the production process, enabling faster turnaround times without compromising on design complexity. This not only benefits small businesses aiming to meet customer demands but also large-scale operations looking to optimize their output. The precision and efficiency of DTF Wash Tests make it a game-changer in the industry, fostering better results and a more sustainable approach to printing on dark fabrics.

Best Practices for Conducting Effective DTF Wash Tests

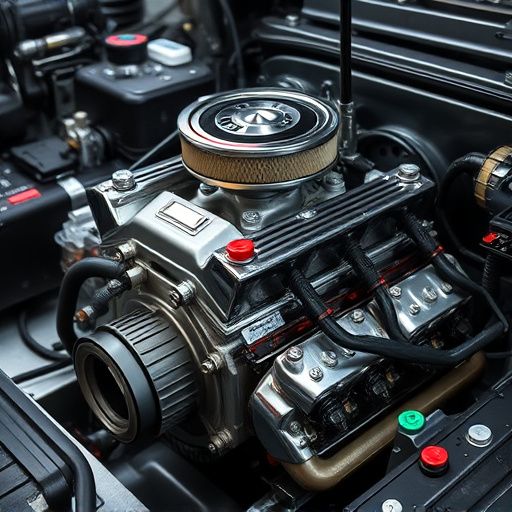

To conduct effective DTF Wash Tests, start by preparing high-quality DTF printer components and utilizing precise settings for optimal results. Ensure clean and static surfaces for the DTF prints, avoiding any debris or contaminants that could interfere with the test. A meticulous approach involves pre-testing materials to validate their suitability for the process.

During the test, carefully apply the DTF transfer film while maintaining even pressure. Choose an appropriate washing cycle, considering factors like water temperature and duration, to simulate real-world conditions accurately. Post-wash inspection is crucial; examine the DTF prints for any fading, peeling, or delamination, comparing them against original standards for thorough analysis.

The DTF Wash Test offers a powerful method to assess product quality and performance, ensuring customer satisfaction. By implementing this test, manufacturers can identify potential issues early in the production process, leading to significant cost savings and improved efficiency. With best practices in place, such as using standardized procedures and well-maintained equipment, consistent and reliable results can be achieved. Incorporating DTF Wash Tests into quality control measures is a strategic move that allows businesses to stay competitive in the market by delivering superior products.